For example, they are often taught separately, with more emphasis on HACCP training and certification than on PRPs. Meanwhile, HACCP and PRPs have gone unacknowledged as interdependent. PRPs are recognized to be an established foundation for the implementation of HACCP. Nowadays, PRPs include environmental criteria. Deficient point HACCP can be implemented. PRPs are encompassing the entire FSMS now, not only operational GHPs as in the past. Prerequisite GHPs must be in place first, before an effective FSMS, hazard analysis, and critical control and operational procedures.

The most frequently identified barriers to implementing Food Safety Systems are: a) Lack of prerequisite programs (ranking #1), and b) Lack of knowledge about HACCP (ranking #2). The potential for food and beverages cross-contamination may occur at any and all food processing steps including transportation from the farm fields to processing facilities, processing steps in the food manufacturing facilities (due to deficient SSOPs, lack of personnel training, deficient GHPs, deficient good process practices (GPP), food packaging and storage). Identified Barriers to Implementing Food Safety Management Systems FSMS Finally, correlation with microbiological criteria is discussed in the context of EU regulation 2073/2005. Moreover, the implementation of management tools such as HAZOP, FMEA, Ishikawa and Pareto will be described. The case study in this document is one such incident. Even though this may seem to be a very basic principle to practice, there have been incidents that this has been neglected which consequently led to cross-contamination and foodborne illness. The aim of this review paper is to show the paramount importance of food safety management systems and their reliance on prerequisite programs for the implementation of effective preventive controls.

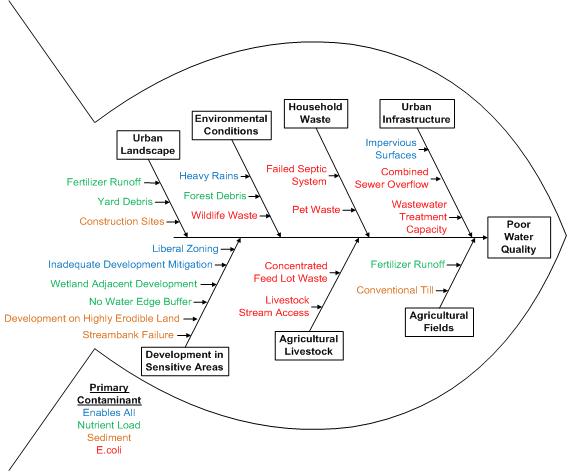

ISHIKAWA DIAGRAM WATER AND SANITATION ISO

ISO 22000:2018 standard allows international trading by assuring reliability, food quality, and food safety.

It is well known that food chain includes organizations that are either directly involved with food or not directly involved with food processing and come in contact with either food or food ingredients. In this way, there has been an integration of HACCP program and principles to quality management systems and prerequisite programs (PRPs) for the improvement of the quality and safety of the food chain in the food industry.įigure 1. ‘Prerequisite programs (PRPs) adapted from What is a Management System? Available online: (accessed 20 June 2021). In September 2005, ISO incorporated Hazard Analysis and Critical Control Point (HACCP) principles for food safety into the ISO 22000 quality management system.

The General Principles of Food Hygiene issued by Codex Alimentarius define Food Hygiene as: “All conditions and measures necessary to ensure the safety and suitability of food at all stages of the food chain Properly applied prerequisite programs, including Good Hygiene Practices (GHPs), Good Agricultural Practices (GAPs) and Good Manufacturing Practices (GMPs), along with training and traceability, should provide the foundations for an effective HACCP system".

0 kommentar(er)

0 kommentar(er)